Rock Cores

Rock cores provide a large “plug” of rock for examination, and allow petroleum geologists get a much better look at the rocks deep in a well. They are much more valuable than the small drilling chips called well samples, or rock cuttings, that are retrieved during drilling. When the geologist wants a better look, she will order that a “core” be taken from the well. A core lets a geologist see the rock just as if it was a fresh piece recently chipped off of a surface outcrop.

Cores are very valuable sources of information. These big hunks of rock let the geologist find out exactly what rocks are present, instead of educated guessing — as must be done with well samples. The PG can clearly see the boundaries between sandstone, limestone, and shale. If one of the formations contains oil, the PG can usually tell by looking at the core. The presence of oil is a big event, and all oil “shows” will be reported back to the main office right away!

The geologist will examine the core at the well site carefully. Then, a full quantitative analysis of the core is undertaken. The core is taken back to a laboratory after it is recovered, and tested in many different ways. Very accurate measurements of the actual porosity of the rock — as well as the amount and types of oil and water in the pores — can be obtained. If desired, parts of the core can be sliced thinner than a human hair, mounted on a glass slide and made into a thin-section, and viewed under a microscope to determine the exact rock type and what microfossils might be present. This is all very precise data that is very useful to the petroleum geologist.

Conventional Coring Bits

Taking a conventional rock core requires that the drilling pipe be pulled out of the well (tripped out). Then, the regular drill bit is removed from the end of the drilling string. The rotary drill bit is replaced with a core bit (left), which is capable of grinding out and retrieving the heavy cylinder of rock core. The core bit is usually coated with small, sharp diamonds that can grind through the hardest rock. A core bit cuts very slowly through the rock.

Taking a conventional rock core requires that the drilling pipe be pulled out of the well (tripped out). Then, the regular drill bit is removed from the end of the drilling string. The rotary drill bit is replaced with a core bit (left), which is capable of grinding out and retrieving the heavy cylinder of rock core. The core bit is usually coated with small, sharp diamonds that can grind through the hardest rock. A core bit cuts very slowly through the rock.

The coring bit is studded with diamonds on the “business end.” These diamonds, the hardest substance known to man, grind away the rock in tiny chips. Notice the large hole in the center of the bit. This hole contains the core. As the bit moves down through the rock, the bit and the drilling pipe above it encase the core inside the steel core “barrel”.

Coring is very expensive, because of the slowness of coring and the expensive diamond bits that must be used. So, geologists only take cores when it is absolutely necessary. The PG always enjoys coring a well, because she can can get closer to the rocks that are so important!

Conventional Rock Cores

Whole Core Samples

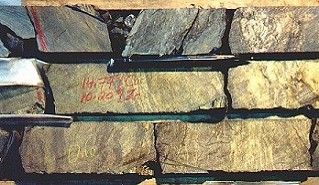

A conventional core is a solid cylinder of rock taken from the hole, about 4-5 inches in diameter, and a single core will usually be about 30 feet long. Sometimes, a PG will order several cores in a well, so the total amount of cored rock may amount to hundreds of feet.

Here is a picture of a whole core, loaded into storage boxes. The core is carefully labeled as to depth. Later, the core may be slabbed, or cut so that flat surfaces are visible.

Slabbed Core – These Cores Just Happen to Contain Gold

A slabbed core is simply a core that was sawn down the middle by a diamond rock saw. Cutting the core to show the fresh, flat, surface allows the PG to see things in the core much more clearly. He is usually looking for indicators that will tell him what environment the rock was formed in…such as a beach, a sand bar, or a river system. He will also note grain sizes, small fossils, and burrows caused by worms or other marine life. He will look (and smell) very carefully for the presence of oil in the rock, or any hint of gas bubbles.

Engineers at the company can use the core data to design elements of the well completion. Additionally, if the reservoir eventually undergoes “secondary recovery” later, the core data is invaluable in designing the water or carbon dioxide flood.

Sidewall Rock Cores

Another type of coring technology is available, called sidewall coring. This method is cheaper than the rotary coring methods shown above, but does not give the geologist quite as much data. However, cores can be taken in hours, instead of days!

To take a sidewall core, a slim coring tool on a wireline is run into the hole, often during the time when the well is logged. The sidewall coring tool tool may be of two general types; either rotary sidewall or percussion sidewall.

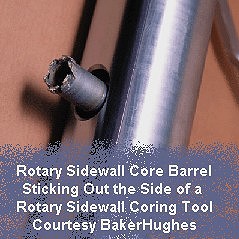

Rotary Sidewall Coring

Rotary Sidewall Coring Tool

The rotary sidewall method uses a small robotic core bit (about one inch in diameter) to bore a core sideways into the formation. The core is then “popped” loose and withdrawn into the main coring tool where the plug is retrieved and stored. Then the tool is moved to another spot in the hole, and the robotic bit is again extended and used to take another core.

The rotary sidewall coring tool can recover numerous sidewall cores in one trip. Each sample is isolated for positive identification, and a summary output at the surface lists all the samples with the exact depth and time each was taken.

Rotary sidewall coring yields cores that are almost as good as conventional cores, except for the size. While porosity and permeability can easily be determined, the geologist will have a much harder time identifying the environment of deposition.

Percussion Sidewall Coring

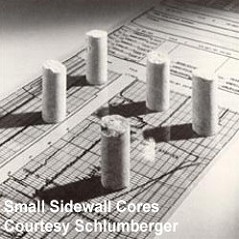

Sidewall Cores

The percussion method of sidewall coring uses a high explosive charge to propel a short core barrel into the formation with a lot of force, at extremely high speed. The core barrel is embedded in the rock, then withdrawn by a strong wire. A short rock plug is pulled out, and retrieved into the tool. Typically, cores about 1″ in diameter and 1″ to 2″ long can be retrieved with this method. Several dozen “shots” will be available on a percussion-core wireline tool. This type of sidewall coring is very fast, which means it is usually the cheapest way to get a core. However, the tremendous force required to penetrate the rock can result in some damage to the rock structure.

Converting the Cores Into Hard Data

A Core Laboratory Contains Many Instruments for Measuring Core Properties

After the cores are retrieved, they are taken to a core laboratory. The core laboratory has the ability to run dozens of tests on on the new cores.

The core lab will measure all the core properties and return a detailed report of porosity, permeability, oil and gas saturation, and many other factors. The petroleum geologist can then integrate this hard data into his cross-sections and maps.