Well Samples

How We Get Well Samples

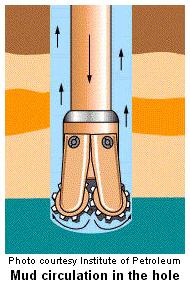

Every time a well is drilled, the petroleum geologist watches the drilling of the hole and makes careful records of all the rocks and formations that are drilled through. The geologist is able to examine the rocks cut by a drilling bit, because wells are drilled using a “mud system”. It’s quite simple. Look  at the picture on the left. The drill bit and pipe are hollow. A mixture that looks like mud (that’s why we call it “mud”) is forced down the drill pipe to the bottom of the hole. As the rock bit grinds its way down, it cuts off small

at the picture on the left. The drill bit and pipe are hollow. A mixture that looks like mud (that’s why we call it “mud”) is forced down the drill pipe to the bottom of the hole. As the rock bit grinds its way down, it cuts off small pieces of rock. The mud comes out the drill bit and flows back to the surface, carrying the well samples, or “cuttings”, with it. The mud serves to lubricate and cool the bit, and also bring the important rock cuttings to the surface.

pieces of rock. The mud comes out the drill bit and flows back to the surface, carrying the well samples, or “cuttings”, with it. The mud serves to lubricate and cool the bit, and also bring the important rock cuttings to the surface.

The well samples received at the surface are the first indication of whether or not the hole may turn out to be a producing well!

Drill Bits Carve Out The Well Samples

Tri-Cone Toothed Drill Bit

Here is a picture of a typical drill bit, called a “three-coned bit,” or a “Tricone (try-cone).” As the bit rotates at the end of the drill pipe, the sharp teeth cut pieces of rock from the hole.

For very fast penetration, particularly in shales, a special (and expensive) bit called a PDC bit (polycrystalline diamond compact) is sometimes used. This bit has carbide or man-made industrial diamonds set in fixed blades. The cutters simply scrape the rock away during drilling, and do not rotate and grind the way the cones of a tri-cone bit do.

man-made industrial diamonds set in fixed blades. The cutters simply scrape the rock away during drilling, and do not rotate and grind the way the cones of a tri-cone bit do.

Bits are constructed of extremely tough and heavy materials to withstand all the abuse they are subjected to downhole.

Bits Are Constructed of Heavy-Duty Materials

Drilling bits are constructed of extremely tough and heavy materials to withstand all the downhole abuse.

Drill bits wear out relatively rapidly, given the hard work they are called on to do. Most wells will require several drilling bits (and several trips of the drill string – taking the pipe out of the hole to replace the bit) to reach the bottom of the hole.

Smaller bits are used as the hole goes deeper and various casings are set. For instance, the well may start drilling with a 10 3/4″ bit, set casing (and cement it), switch to a 7 5/8″ bit, set casing and cement again, then drill out from under that casing with a 5 1/2″ bit.

The deeper the well, the larger the bit size must be at the top of the hole! Some holes are started that are 3 feet in diameter!

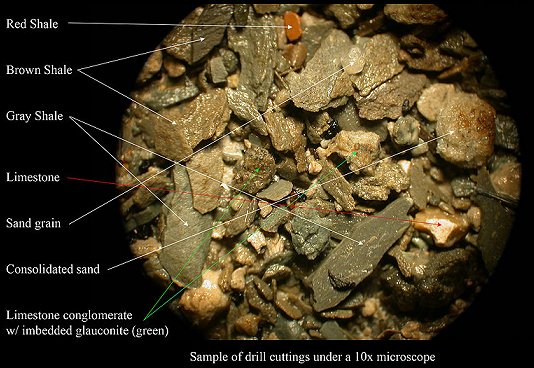

Examining The Well Samples

Well samples/cuttings are carefully examined under a microscope. Then the sample descriptions are carefully transferred to the Mud Log

After the cuttings reach the surface, the petroleum geologist or the mud logger looks at them carefully through a microscope to see whether the rocks being drilled are sandstone, limestone, or shale, whether they have porosity, and whether any oil can be seen in them. They also do some simple chemical tests to help them decide what they are seeing. Usually, a sample is examined every ten feet.